Upgrade Your Electroforming Setup with This Ingenious Solution

-Anode cage-

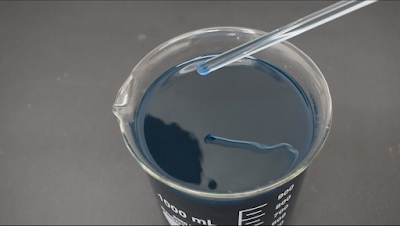

Electroforming is an exciting process that allows you to create intricate copper objects with unique textures and shapes. However, connecting multiple copper anodes to the power source can be a real challenge. That's where an anode cage comes in.

An anode cage is a conductive grid made of a metal, such as titanium or platinum, that is inert to the acidic environment of the electroforming tank. It connects multiple copper anodes together and holds them securely in place during the electroforming process. This eliminates the need for clips and wires, simplifying the setup and improving the overall efficiency of the electroforming process.

To make an anode cage, start by cutting a plane grid of titanium or platinum in half and shaping it to fit the dimensions of your electroforming container. You can use an angle grinder and a hammer to shape the cage. Once you have the shape you need, prepare an anode bag that fits the cage and slip it in easily with the help of two soft plastic sheets.

Fold the hanging part of the cage and attach the positive pole clip to the outside of the tank. The cage acts as a framework that securely holds the copper anodes in place, so there's no need to worry about them moving around during the electroforming process. Another advantage of using an anode cage is that all the unused copper pipe pieces can be used, eliminating waste.

If you are looking to buy an anode cage for your electroforming projects, you can find them easily on popular online marketplaces.

Here's my affiliate links:

Titanium mesh 30x20x1cm: https://ebay.to/3C7qYOR

Titanium mesh 30x20x0.5cm: https://ebay.to/3IVQUAR

Titanium mesh 20x5cm (small): https://amzn.to/42tnaCj

The anode cage is a versatile and efficient solution for the electroforming process. With its help, you can simplify your setup, improve efficiency and eliminate the need for additional clips. Using an anode cage will save you time and helps to reduce waste by utilizing unused copper pipe piece.

If you want to see how to set up the anode cage in your electroforming tank, check out the video on YouTube.

Don't forget to subscribe to my channel for more electroforming tips and tutorials.

I wanna thank everyone who has read this blog and has shown an interest in electroforming. I hope that you have found it informative and helpful. Happy electroforming! CuForming!

.jpg)