How to Set Up Your Power Supply and Calculate the right Current for Electroforming

Hey there, fellow electroformers! Today, we're diving into the electrifying world of current. If you've ever wondered how to get that perfect copper coating on your jewelry, you're in for a treat. I'm about to spill the beans on how to master the current. Grab yourself an adjustable power supply, mistakenly called rectifier, to give the current needed for your objects to get coated and let's get started.

Supplies you may need:

Adjustable Power Supply: https://amzn.to/49kZy7m | https://ebay.to/47ipVJu

Transparent paper: https://amzn.to/3QmHykk | https://ebay.to/3FHtlcX

Measuring the Objects: Two Ways to Rule Them All

Creating stunning copper art pieces

through electroforming, starts with measuring your objects. Before you dive

them into the electroforming tank, you need to understand the relationship

between the object's surface and the current. This is what ensures that you'll

get the perfect copper coating you've been dreaming of.

The juicy part is figuring out how to measure your objects and dial in the

right current.

- First Way

If your objects are all nice and symmetrical, you can use basic geometric formulas, like circles, triangles, rectangles, to calculate the surface area. Use the appropriate formulas for each shape to calculate the surface area. It's a perfect method for objects that fit neatly into these geometric categories.

- Second Way

What if you've got an object that's as irregular as your Monday morning bedhead? No worries! Grab a piece of paper, trace the object's silhouette, and draw squares all inside it. Choose the measuring system you like, the metric system, or the imperial one, and fill the shape by adding up squares, half squares, and quarter ones. Then sum them, one by one, to calculate the total surface area of your object. You can use a transparent sheet on a squared mat, like I do, to make it easier.

If the object has two faces, double your calculation since both sides will get the copper on.

No need to get too precise; it's not a math competition. Approximations will do the trick to get the ball rolling. You can always fine-tune your current later.

Surface and Current Relationship

The secret recipe for of a good relationship between these two parameters, is The Constant Values of Current. I have it for both centimeters and inches, so you've got all your bases covered. This is gonna bring you to the electroforming success!

For Centimeters (cm): There's a sweet spot for current values that work like a charm for most electroforming solutions on the market, as well as those you might whip up for your own DIY projects. To make life a bit easier, I've expanded the range around this number to give you some wiggle room and avoid any unexpected hiccups.

Here are the constant values to multiply by the centimeter square:

- Minimum: 0.004 amperes

- Medium: 0.02 amperes

- Maximum: 0.04 amperes

So, for example, if your object's surface area measures 30 centimeters square, you'd be looking at:

- Minimum: 0.12 amperes

- Medium: 0.60 amperes

- Maximum: 1.20 amperes

For Inches: If you prefer working in inches, I've got you covered as well. Here are the constant values for square inches:

- Minimum: 0.01 amperes

- Medium: 0.05 amperes

- Maximum: 0.1 amperes

So, if your object's surface area is measured in square inches, apply these values accordingly to get the right current for your electroforming experience.

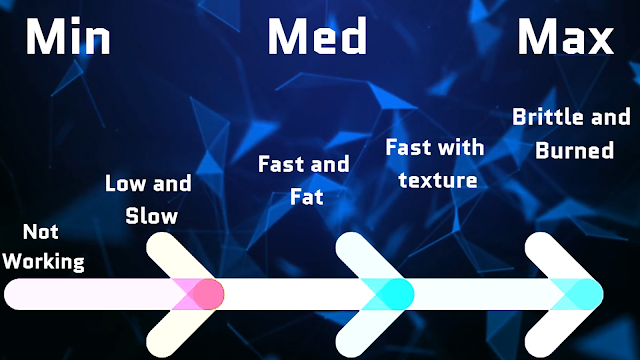

The current levels you choose can have a profound impact on the outcome of your copper creations. Understanding how copper behaves at different current levels is the secret to master this art.

Minimum Current Level

When you set your current at the minimum recommended value, it's like putting your electroforming process into a slumber state. At this level, the copper deposition is minimal, and it's often not even noticeable. This means that if you want your object to start working, you'll need to increase the current.

When you set your current close to the minimum, you're essentially taking things slow and steady. This approach allows the copper coating process to work with patience. You'll get a copper coat that's not only strong and precise, but also one that highlights and emphasizes the original texture of your object. It's like bringing out the unique details and features of your creation, making them stand out.

Going below the minimum value of current in the electroforming process means setting the current lower than what's required for the reaction to take place effectively. At this extremely low current, copper ions won't be deposited onto your object, and you won't see any copper coating forming.

When in doubt, remember that low and slow is a choice that ensures your electroformed piece excellence, and it will avoid any possible trouble you could encounter.

Medium Current Level

At the medium current level, you'll achieve a consistent and controlled deposition of copper onto your object. Setting your current at the medium value strikes a balance between speed and texture. This level offers the best chance of speed without causing issues like burnt or brittle copper with some deprivation. The copper coat that forms at this level will be thicker, adding an extra layer of copper. This thickness can mask some of the finer details and original texture of your object, making them less evident and pronounced. Choosing the medium value is opting for a blend of speed and substance with the loss of intricate details.

Maximum Current Level

Setting your current at the maximum value means you're pushing the electroforming process to its limits. It's like unleashing a burst of energy. It can indeed lead to an irregular deposition of copper, often resulting in bumps and peaks on the copper coat. This can create a textured or uneven surface on your electroformed object, which may or may not be the desired effect for your artistic creation. It's crucial to understand the potential outcomes and make an informed choice when selecting the current value for your electroforming project. However, it's important to exercise caution at this level. Going near or above this level can cause issues such as a burnt or brittle copper coat, which may cause further issues on the piece or even to your electroforming solution. So, if you're considering this level, do so with care and monitor the process closely.

It's essential to remember that these values are not strict rules, but rather guidelines to help you navigate your electroforming journey. The actual current levels can vary depending on the specific electroforming solution, power supply, and setup you're using. It's all part of the creative process, and sometimes a bit of trial and error is needed to find the perfect balance

How to set up your power supply

Now that you've understood about all the calculations, it's time to put your hands on the device that produce the current. It can be set in two different ways, for different experiences.

It's time to talk about CC mode (Constant Current) and CV mode (Constant Voltage).

CC Mode:

With the CC mode, the goal is to achieve a consistent deposition of copper ions onto your objects. This is the go-to method for many electroformers, especially beginners. It's relatively easy to control and allows you to let your setup run unattended for extended periods.

Here's how to set up your power supply for CC mode:

- Voltage Knobs: Turn these all the way up, as high as they go.

- Current Knobs: Turn these all the way down, as low as they go.

Once you've got your setup in CC mode, your LED indicator named CC will stay on, only after you connect your object and dip it into the electroforming solution.

This setup ensures that your current stays constant, having control over the amperes.

Use the coarse knob for consistent, gradual increases in current, and the fine knob for more precise adjustments. By understanding how they work, you can fine-tune your amperes as you wish.

Now, you can let your setup do its thing for hours or even days.

CV Mode: Constant Voltage Mode

In CV mode, the process is a bit different. You'll need some patience and a watchful eye because, unlike CC mode, you can't simply set the current at your desired value right from the start. You've got to check the process constantly

Here's how to set up your power supply for CV mode:

- Current Knobs: Crank these up, turning them all the way to the max.

- Voltage Knobs:Turn these all the way down, as low as they go.

The LED indicator named CV will stay on.

The current in CV mode increases over time as the resistance decreases as copper gradually coats the surface. You'll need to start at the lowest value of current and wait for the graphite to get coated in copper before you can start dialing up with the right level.

Here's how it typically goes:

- At first, the current must be kept on low because there's the graphite creating resistance.

- As the copper deposition progresses, the resistance decreases, and the current starts to climb.

- Eventually, the current will stabilize, and you'll have a consistent flow.

After this, you're in control, and you can decide whether you want to keep the current at this level or dial it up to a medium or higher value. In CV mode, you need to keep a close eye on your setup and check it regularly, allowing for more flexibility in adjusting the current as you go on the cost of your free time.

So, there you have it – the two main modes for controlling the current in electroforming. Whether you prefer CC or CV mode, you're well on your way to mastering this art.

Possible Issues

Electroforming is an exciting journey, and you have to consider that it can have its fair share of challenges. Here's the potential pitfalls along the way caused by current.

- Too Low Current

When your current is set below the minimum recommended value, you won't get any copper deposition on your object. So, don't skimp on the current; make sure it's above the minimum to get the party started.

- Too High Current

On the flip side, if you crank up the current to extreme levels, you'll end up with a burnt and brittle copper coat that resembles a bad hair day. Keep it within the recommended maximum value to avoid this less-than-ideal outcome.

- Anode Worn-Out

Anodes play a crucial role in the electroforming process. If they wear out over time, and you don't add more, it can lead to low current and instability. This can be noticed using the CV mode. Keep an eye on your anodes and replace them when needed.

- An Unexpected Look

Sometimes, electroforming can surprise you. Objects electroformed at different current values can result in varying textures and finishes. This unpredictability is part of the charm, but can be a challenge if you're seeking for consistent results. The copper coating might be smooth and sleek, or it might sport a rugged and textured appearance. When you push the boundaries and crank the current up, the outcome can result in an irregular deposition of copper, with bumps and peaks on the copper coat.

You're finally set to conquer the world of electroforming. Whether you're a pro or just starting, the knowledge of current is in your hand. Remember, the numbers and values we shared are a guideline because every setup and solution is unique.

Thanks for joining me on this electrifying journey! I appreciate you, and I hope you're feeling ready to electroform like a champ.

Don't Forget to Watch My YouTube Video!

You can see in details the demonstration of all this on my YouTube channel. Go ahead, click that link, and I'll see you there! Enjoy, and happy crafting!

Thank you all by CuForming!